Steel Products

Billet

Billets are semi-finished long products that are rectangular, circular, or square in shape, high-quality Billets are produced through a continuous casting process and they need to be furtherly processed by rolling to become a final product as rebars, wire rod, sections, and other profiles.

Sector:

Used as raw materials or feedstock in rolling the rebar, wire rod, and other metal-processing operations.

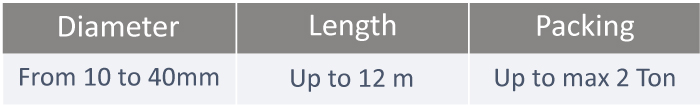

Billet Specification

Billet Grades

Rebar

Steel reinforcement bars or rebar’s are used to improve the strength of the concrete, It is produced in different diameters and grades based on the application. Rebars strength and other mechanical properties can be controlled by the addition of different elements during alloying and controlling its process parameters as well as thermo-mechanical rolling to meet the end-use.

Despite being hidden in buildings, bridges and so many other objects, rebars is a product used everywhere in almost everything around us.

Sectors

Construction.

Infrastructure.

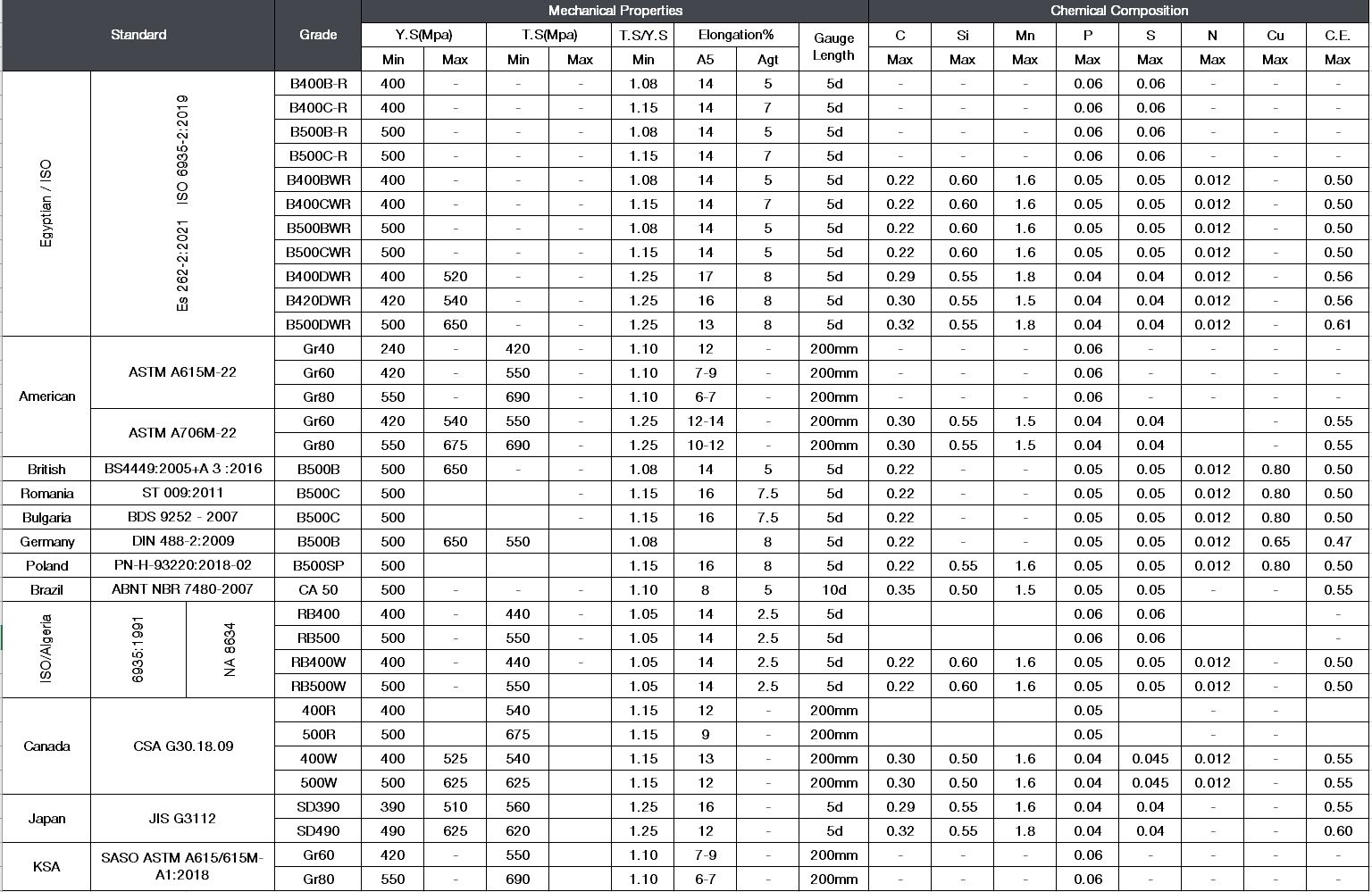

Rebar Specifications

| Diameter | Length | Packing |

| From 8 to 40mm | Up to 15 M | Up to Max 2 Ton |

Rebar Grades

Wire Rod

A hot rolled alloy or non-alloy steel product, produced from billets. Particularly fine cross-sections may be achieved by subsequent cold forming. Wire rod is wound into coils and transported in this form. Unlike rebars, Wire rod is used in many applications rather than reinforcing concrete structures and is produced in different grades and qualities based on the required application.

Sector:

Reinforcing concrete structures.

Aluminum and Copper rod.

Welding electrodes.

Drawn and galvanized wire.

Nails, bolts, and tacks.

Sling wire rope.

Electrical components and household goods.

Electric cable armoring.

Furniture springs.

Automotive components.

Fasteners and fixings.

Wire mesh.

Aviation.

Wire Rod Specifications

| Size | Coil weight | Inner coil Diameter | Outer coil Diameter | Length |

| 5.5 to 14 mm | Around 1.5 Ton | 85 to 100 cm | 100 to 130 cm | 100 to 130 cm |

Wire Rod Grades

| Steel Grade | Chemical Composition (w.t%) | |||||

| C | Si | Mn | P | S | ||

| AISI 1006 | Min. | 0.00 | 0.00 | 0.25 | 0.000 | 0.000 |

| Max. | 0.08 | 0.10 | 0.40 | 0.040 | 0.050 | |

| AISI 1008 | Min. | 0.00 | 0.00 | 0.30 | 0.000 | 0.000 |

| Max. | 0.10 | 0.20 | 0.50 | 0.040 | 0.050 | |

| AISI 1010 | Min. | 0.08 | 0.00 | 0.30 | 0.000 | 0.000 |

| Max. | 0.13 | 0.30 | 0.60 | 0.040 | 0.050 | |

| AISI 1012 | Min. | 0.10 | 0.00 | 0.30 | 0.000 | 0.000 |

| Max. | 0.15 | 0.30 | 0.60 | 0.040 | 0.050 | |

| AISI 1013 | Min. | 0.11 | 0.00 | 0.50 | 0.000 | 0.000 |

| Max. | 0.16 | 0.30 | 0.80 | 0.040 | 0.050 | |

| AISI 1015 | Min. | 0.13 | 0.00 | 0.30 | 0.000 | 0.000 |

| Max. | 0.18 | 0.30 | 0.60 | 0.040 | 0.050 | |

| AISI 1017 | Min. | 0.15 | 0.00 | 0.30 | 0.000 | 0.000 |

| Max. | 0.20 | 0.30 | 0.60 | 0.040 | 0.050 | |

| AISI 1018 | Min. | 0.15 | 0.00 | 0.60 | 0.000 | 0.000 |

| Max. | 0.20 | 0.30 | 0.90 | 0.040 | 0.050 | |

| AISI 1020 | Min. | 0.18 | 0.00 | 0.30 | 0.000 | 0.000 |

| Max. | 0.23 | 0.30 | 0.60 | 0.040 | 0.050 | |

| AISI 1022 | Min. | 0.18 | 0.00 | 0.70 | 0.000 | 0.000 |

| Max. | 0.23 | 0.30 | 1.00 | 0.040 | 0.050 | |